OK, so when someone says they’ve been skimming, it’s not usually a good thing. However, when it’s skimming fuel from a monitoring well on petrol station, that’s definitely beneficial.

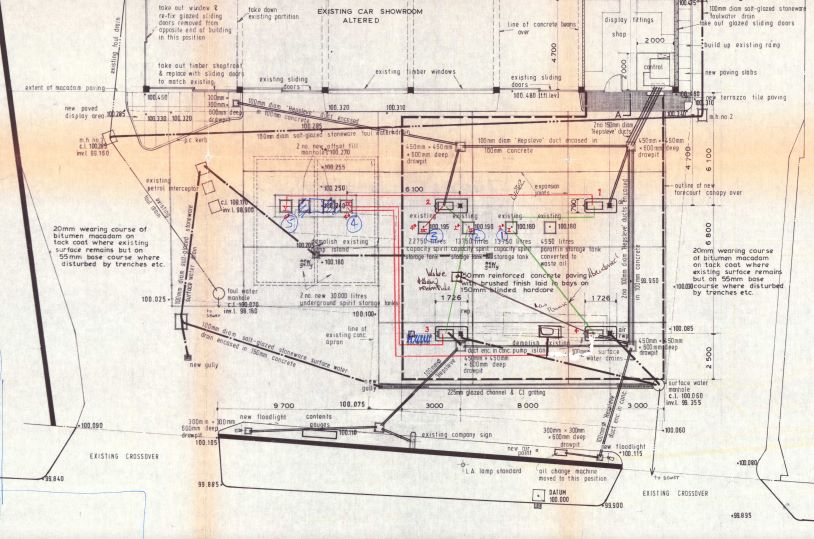

We identified the fuel during a site audit, carried out in response to complaints about petrol odours in off-site (BT and Thames Water) service ducts. Contaminants often track/migrate through ducting and service trenches, leading away from the original source. In this case, our detective work was able to trace the source of the odours back to a fuel leak from the nearby filling station.

Our UKAS accreditted laboratory carried out forensic analysis of the recovered fuel in order to determine it’s age and composition, allowing us to further focus future infrastructure and ground investigation efforts on possible sources of the leak from the filling station.

Being able to seemlessly integrate both site investigation and laboratory testing in this way resulted in significant time and cost savings for our client.

If you’d like to know more about our unique approach to assesment of contaminated land, please contact James Edley.